- Joined

- Dec 22, 2004

- Messages

- 1,713

In the downtime between tank inhabitants, I renovated the plumbing on my 75 gallon tank. Pictures are a lot easier now following Black Friday

The previous configuration can be seen in all its glory in the following thread:

Tank photos - finally!

That configuration was basically a proof-of-concept. Since the basic idea worked, I kept it but cleaned up the plumbing and made things a little smoother.

The tank looks nice in the dark. Recap: Oceanic 75 gallon tank with a custom external glass overflow. Primary biofilter is a DIY wet/dry made from a 5-gallon bucket, containing about 4 gallons of bioballs (visible to the right). Other filtration includes an AM Turboflotor 1000 protein skimmer, a filter sock and chaetomorpha.

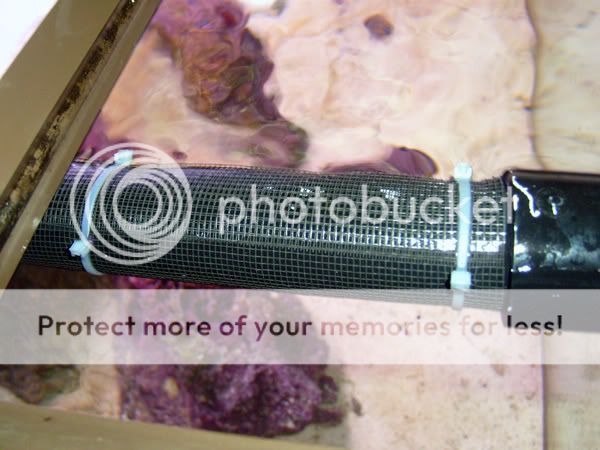

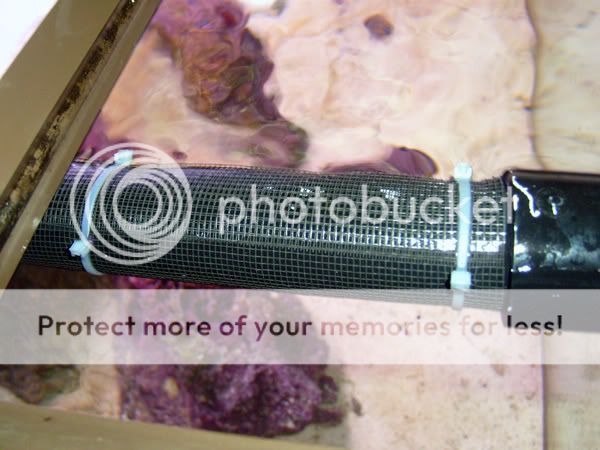

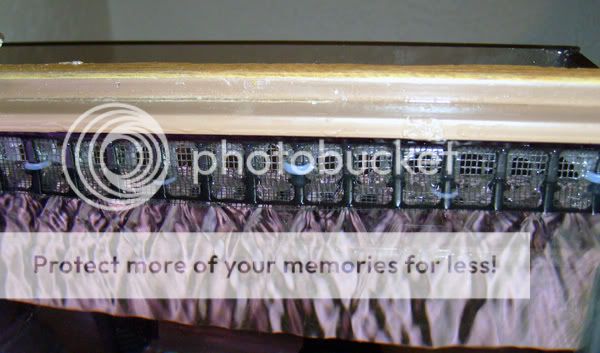

Two images of the spraybar that returns water to the display from the sump. The Mag-7 pump manages between about 350 and 400 gph. The spraybar is octo-proofed with fiberglass window screen and zip-ties.

Here's an image of the overflow and the biofilter. The overflow was made by drilling 24 small slots near the top of the tank and building a glass box around them. Two bulkhead holes in the bottom of the overflow box accommodate standpipes.

The line going into the biofilter contains a ball valve to throttle the flow and a filter sock to prevent detritus from decaying inside the filter.

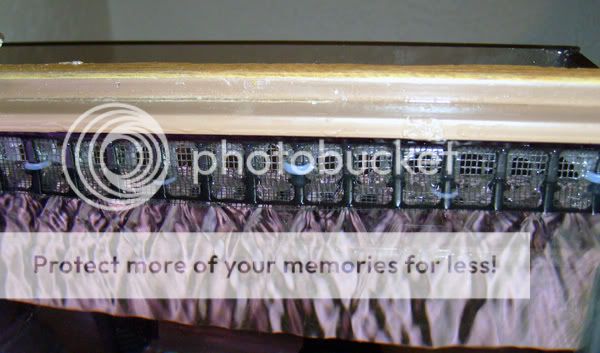

Here's a closeup of the slots as seen from inside. Octoproofing is more fiberglass window screen, sandwiched behind a frame of rigid plastic and held in place with zip ties. A previous incarnation just had the window screen and zip ties, but it would be too easy for an octopus to peel the screen back and climb through. The plastic frame won't make that impossible, but much less likely.

Here are the slots from just outside the tank. You can see the backs of the zip ties.

A short (1 mb) video of the overflow at work.

This is what I call a linear plumbing diagram. The plumbing takes so many crazy twists and turns, sometimes--like Eagon Spangler's slinkey--its easier just to see it straightened.

The bypass line coming from the overflow is an emergency line in case the main line is plugged. The bypass line coming out of the filter (the "wet/dry overflow line") keeps the water level in the filter a bit lower than it otherwise would be. The ball valve on that line keeps just enough water in the bottom of the filter to keep it from "flushing."

Here are the three lines coming into the stand. In the system's previous incarnation, a buttload of 45 degree elbows maneuvered these lines around the back of the stand. This time I shored up the inside of the stand with some 1x4s and drilled straight through. Someday when I have a house and a basement sump the PVC can run straight down from the overflow into the stand and won't be an eyesore.

Here's the view of the lines coming in from the inside. The line in the right is the wet/dry overflow line. The one on the top left is the emergency bypass line, and the one right below it is the skimmer bypass line. You can see the branch coming up and then down into the sump carrying the flow from the filter that the skimmer can't take. The air line tube is the auto-topoff.

Here's a view of the sump. You can see the skimmer and its Oceanrunner needlewheel pump amidst the mess of plumbing. On the left-hand side is the refugium and return pump.

The previous configuration can be seen in all its glory in the following thread:

Tank photos - finally!

That configuration was basically a proof-of-concept. Since the basic idea worked, I kept it but cleaned up the plumbing and made things a little smoother.

The tank looks nice in the dark. Recap: Oceanic 75 gallon tank with a custom external glass overflow. Primary biofilter is a DIY wet/dry made from a 5-gallon bucket, containing about 4 gallons of bioballs (visible to the right). Other filtration includes an AM Turboflotor 1000 protein skimmer, a filter sock and chaetomorpha.

Two images of the spraybar that returns water to the display from the sump. The Mag-7 pump manages between about 350 and 400 gph. The spraybar is octo-proofed with fiberglass window screen and zip-ties.

Here's an image of the overflow and the biofilter. The overflow was made by drilling 24 small slots near the top of the tank and building a glass box around them. Two bulkhead holes in the bottom of the overflow box accommodate standpipes.

The line going into the biofilter contains a ball valve to throttle the flow and a filter sock to prevent detritus from decaying inside the filter.

Here's a closeup of the slots as seen from inside. Octoproofing is more fiberglass window screen, sandwiched behind a frame of rigid plastic and held in place with zip ties. A previous incarnation just had the window screen and zip ties, but it would be too easy for an octopus to peel the screen back and climb through. The plastic frame won't make that impossible, but much less likely.

Here are the slots from just outside the tank. You can see the backs of the zip ties.

A short (1 mb) video of the overflow at work.

This is what I call a linear plumbing diagram. The plumbing takes so many crazy twists and turns, sometimes--like Eagon Spangler's slinkey--its easier just to see it straightened.

The bypass line coming from the overflow is an emergency line in case the main line is plugged. The bypass line coming out of the filter (the "wet/dry overflow line") keeps the water level in the filter a bit lower than it otherwise would be. The ball valve on that line keeps just enough water in the bottom of the filter to keep it from "flushing."

Here are the three lines coming into the stand. In the system's previous incarnation, a buttload of 45 degree elbows maneuvered these lines around the back of the stand. This time I shored up the inside of the stand with some 1x4s and drilled straight through. Someday when I have a house and a basement sump the PVC can run straight down from the overflow into the stand and won't be an eyesore.

Here's the view of the lines coming in from the inside. The line in the right is the wet/dry overflow line. The one on the top left is the emergency bypass line, and the one right below it is the skimmer bypass line. You can see the branch coming up and then down into the sump carrying the flow from the filter that the skimmer can't take. The air line tube is the auto-topoff.

Here's a view of the sump. You can see the skimmer and its Oceanrunner needlewheel pump amidst the mess of plumbing. On the left-hand side is the refugium and return pump.